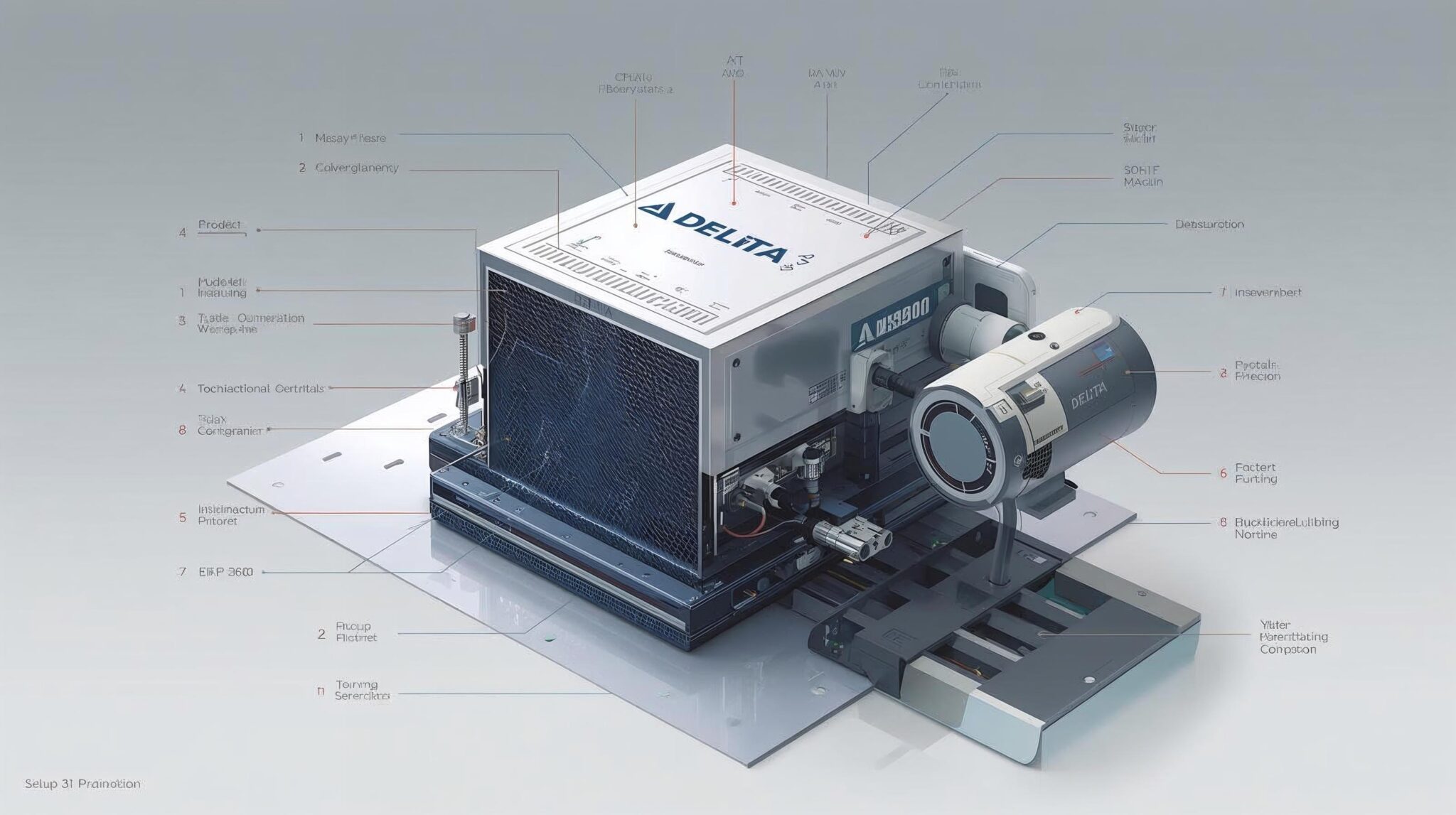

Delta MS300 Setup Guide – Wiring, Programming & Parameters

The Delta MS300 is one of the most compact and feature-rich VFDs in its class. Whether you’re using it for conveyors, fans, pumps, or small automation systems, knowing how to set it up correctly is key to reliable operation.

In this guide, we walk you through how to install, wire, and program the Delta MS300 — including basic I/O, motor settings, and application-specific parameters.

📦 Step 1: Check What’s in the Box

Before you begin installation, make sure your MS300 drive includes:

- ✅ The MS300 drive unit (IP20 rated)

- ✅ User manual or quick start guide

- ✅ Removable terminal cover

- ✅ Mounting hardware (if included)

You can access full Delta MS300 documentation here.

🧰 Step 2: Mounting and Installation

Install the MS300 vertically in a clean, dust-free environment with proper airflow. Maintain at least 100 mm clearance above and below the unit. Use a DIN rail or screw-mount directly to your panel backplate.

Note: The MS300 is convection-cooled. Avoid installing above heat-generating components.

⚡ Step 3: Power Wiring

- Input Power: Connect 1-phase or 3-phase 200–240V AC (depending on model)

- Output Terminals: Connect U, V, W to the motor

- Ground: Always ground the drive to reduce EMI and improve safety

Wiring Tip: Use shielded VFD-rated cable for output leads to reduce noise and comply with EMC standards.

🔌 Step 4: Control Wiring (I/O)

The Delta MS300 includes 5 digital inputs (DI1–DI5), 1 analog input, 1 analog output, and 1 relay output.

- 🟢 DI1: Default RUN (Forward)

- 🟠 DI2: Reverse

- 🔵 AI1: 0–10V analog speed reference

- ⚫ DO: Fault or running status

You can configure logic via parameter group 00-10 to 00-15 or use Modbus RTU via the RS-485 terminals.

🎛️ Step 5: Basic Parameter Setup

After power-up, set these key parameters using the built-in keypad or external keypad (optional):

- 00-00: Factory reset (if needed)

- 00-02: Motor control mode (V/F, sensorless vector, etc.)

- 01-00: Base frequency (e.g. 50Hz or 60Hz)

- 01-01: Maximum output frequency

- 01-02: Motor rated voltage

- 01-03: Motor rated current

- 01-04: Motor rated frequency

- 01-05: Motor rated RPM

Pro tip: Match motor nameplate data exactly to avoid faults or underperformance.

🧪 Step 6: Test Run and Tuning

Use the keypad to enter RUN mode and monitor:

- ✔️ Output frequency

- ✔️ Output voltage/current

- ✔️ Drive temperature

Adjust acceleration/deceleration times in 01-09 and 01-10 to suit your application. Fine-tune torque boost or braking via groups 02 and 03.

📌 Need Help Sizing or Programming Your MS300?

Use our VFD Sizing Calculator or contact our team for fast support.

We supply all models of the Delta MS300 Series:

- 🔗 Shop Delta MS300 Inverters

- 📦 In stock now with next-day UK delivery

- 🛡️ 2-Year Warranty on all drives