What Is Sensorless Vector Control in a VFD?

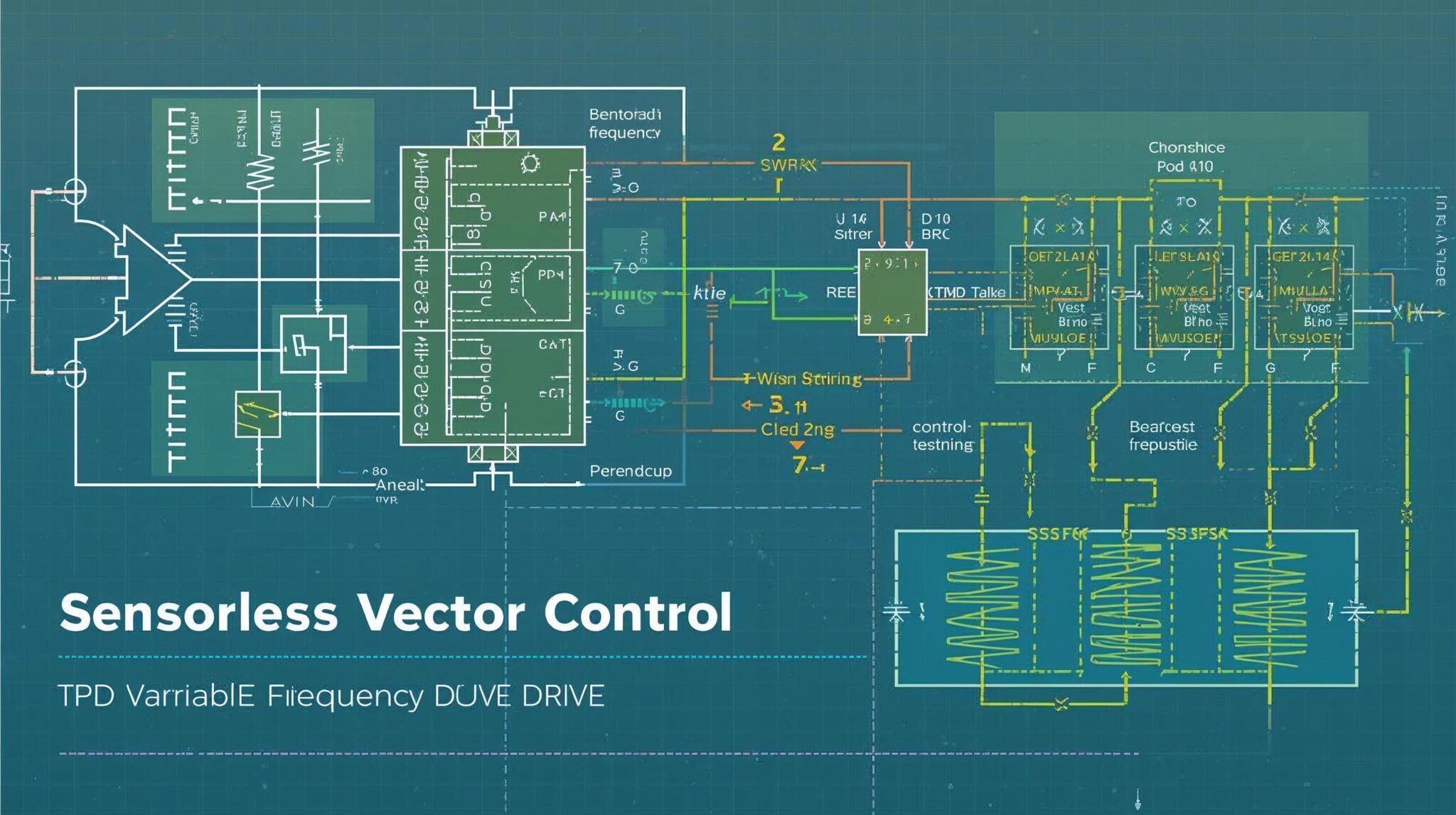

Sensorless Vector Control (SVC) is a motor control technique used in many modern Variable Frequency Drives (VFDs). It delivers high starting torque and dynamic speed regulation — without requiring an external encoder or feedback sensor.

In this guide, we break down how sensorless vector control works, when to use it, and which drives support it.

⚙️ What Is Sensorless Vector Control?

Sensorless Vector Control is a method of motor control that calculates motor shaft position and speed using internal voltage/current feedback — instead of a physical encoder.

By estimating motor parameters in real-time, the VFD can generate torque precisely and respond quickly to load changes. This makes it ideal for applications where speed or torque accuracy is important — but without the cost and complexity of encoder wiring.

🎯 Key Benefits of Sensorless Vector Control

- ✅ High starting torque (up to 200%) without an encoder

- ✅ Smooth low-speed operation with full torque

- ✅ Fast dynamic response to load changes

- ✅ Reduced wiring and hardware costs

- ✅ Improved energy efficiency in variable torque loads

It’s a balance between open-loop (V/F) simplicity and the precision of closed-loop vector control.

📊 SVC vs V/F vs Closed Loop

| Control Mode | Encoder Required? | Torque Accuracy | Application Fit |

|---|---|---|---|

| V/F (Volts per Hz) | No | Low | Fans, pumps, conveyors |

| Sensorless Vector | No | Medium–High | Cranes, hoists, extruders |

| Closed Loop Vector | Yes | High | Positioning, high-speed applications |

🔌 Do You Need Sensorless Vector Control?

You should consider SVC if your application requires:

- 🚀 Strong torque at low speeds

- 🔁 Rapid load changes (e.g. lifts, mixers, extruders)

- 📉 Better regulation than basic V/F mode

- 💸 Lower cost than full closed-loop setups

Common use cases include:

- Material handling and conveyors with frequent stop-start cycles

- Packaging machines with variable loads

- Winders, unwinding stations, and extruders

✅ Drives That Support Sensorless Vector

Most mid-range and premium VFDs support SVC out of the box. These include:

- ABB ACS880 – With high dynamic vector control

- Allen Bradley PowerFlex 753

- Delta MS300 – Sensorless Vector built-in

- Danfoss FC-302 – With Advanced Drive Programming

Note: Many VFDs default to V/F mode. You’ll need to switch to vector mode in the parameters (usually P00-02 or similar).

📌 Conclusion

Sensorless Vector Control bridges the gap between basic V/F control and advanced servo systems. It gives you:

- ⚡ Strong performance at low speed

- 🧠 Adaptive motor control with no feedback device

- 💰 Lower setup costs

Need help choosing the right VFD? Use our VFD Sizing Calculator or contact us today for expert support.

📦 We stock 3,000+ VFDs across all major brands — ready for next-day delivery.