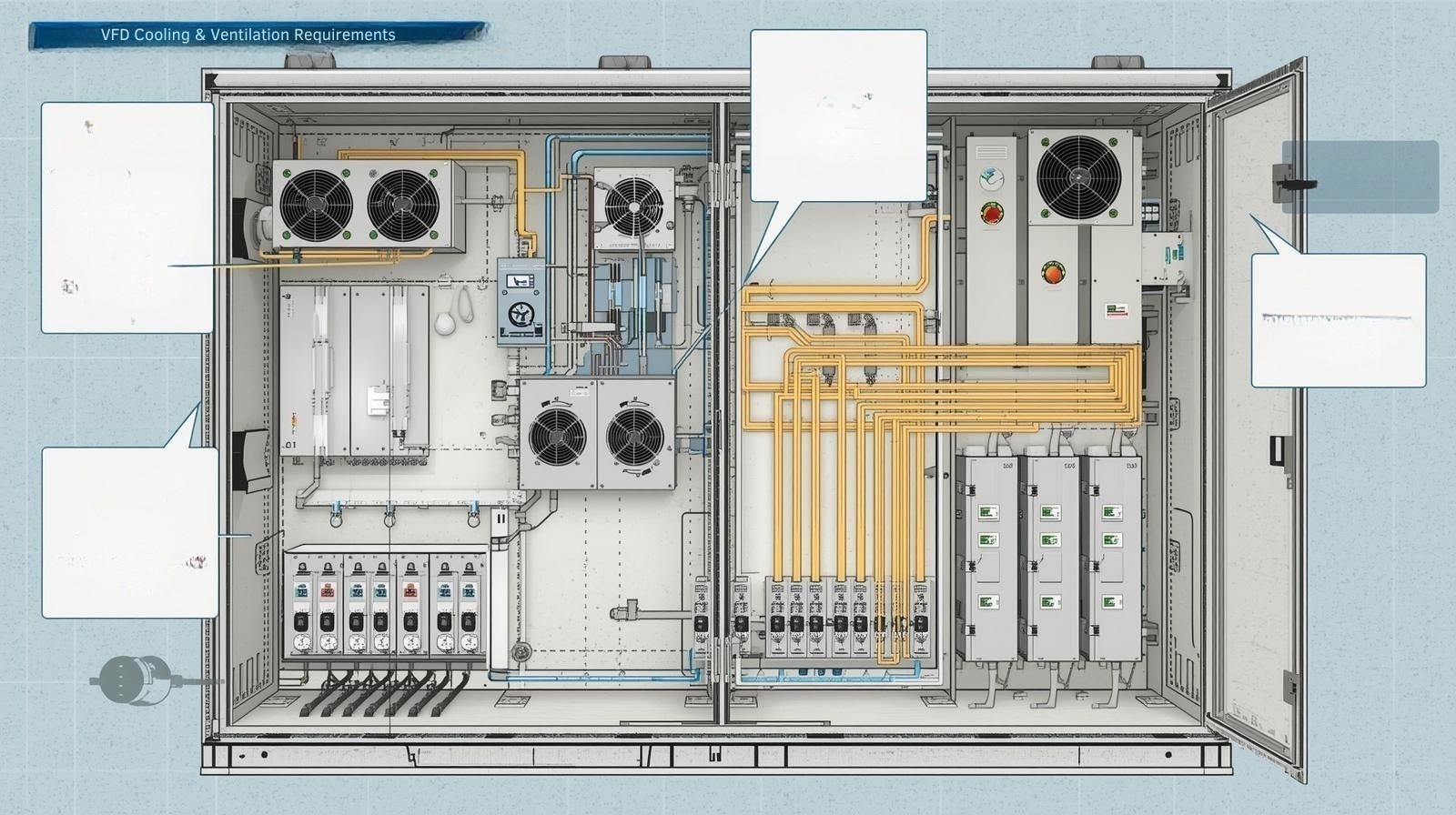

VFD Cooling & Ventilation Requirements: Panel Layout Best Practices Explained

Overheating is one of the most common causes of premature VFD failure — and it’s almost always caused by poor enclosure design, restricted airflow, or incorrect drive selection for the environment.

This guide explains how VFDs dissipate heat, the most common ventilation mistakes, and how to design control panels that keep drives reliable, compliant, and within temperature limits.

Quick Links

- Why heat kills VFDs

- How VFDs are cooled

- Minimum clearance & mounting rules

- Choosing the right enclosure (IP20 vs IP66)

- Control panel layout best practices

- Cooling methods: fans, filters & air conditioners

- Common ventilation mistakes

- Recommended categories & products

- FAQ

Why Heat Is One of the Biggest VFD Killers

VFDs generate heat through switching losses, current flow, and internal components such as IGBTs and DC bus capacitors.

Excess heat causes:

- Capacitor ageing (shortened lifespan)

- Thermal trips and nuisance faults

- Reduced output current capability

- Permanent damage to power electronics

Many failures blamed on “bad drives” are actually caused by poor ventilation — a key issue covered in: VFD Installation Mistakes That Cause Drive Failures

How VFDs Are Cooled

Most VFDs use one of the following cooling methods:

- Forced air cooling: Internal fans move air across heatsinks

- Heatsink conduction: Heat is transferred through the rear of the drive

- External airflow: Cabinet ventilation removes hot air

If airflow is restricted, internal temperatures rise rapidly — even if the drive is correctly sized electrically.

Minimum Clearance & Mounting Rules

Manufacturers specify minimum clearances to allow proper airflow.

Typical requirements:

- Clear space above and below the drive (often 50–150mm)

- No obstruction of ventilation slots or fan intakes

- Vertical mounting unless explicitly allowed otherwise

Stacking drives too close together is a common mistake in compact panels.

Choosing the Right Enclosure: IP20 vs IP66

Choosing the wrong enclosure rating often creates cooling problems.

IP20 Drives

- Designed for clean, ventilated control panels

- Rely on cabinet airflow for cooling

- Require filters or air conditioning in dusty environments

IP66 Drives

- Sealed for harsh environments

- Limited heat dissipation compared to open drives

- Often require derating at higher ambient temperatures

Related guide: IP20 vs IP66 Inverter Drives – Which One Do You Need?

Control Panel Layout Best Practices

- Mount high-heat devices (VFDs, braking resistors) near the top of the airflow path

- Separate power components from control electronics

- Avoid cable congestion near ventilation paths

- Allow space for maintenance and filter replacement

Good layout also improves EMC performance — covered in: VFD EMC Compliance Explained

Cooling Methods: Fans, Filters & Air Conditioning

Panel Fans & Filters

- Low-cost solution for moderate heat loads

- Must be correctly sized and maintained

Heat Exchangers

- Separate internal and external air

- Good for dusty environments

Panel Air Conditioners

- Required for high ambient temperatures

- Used with high-power or densely packed drives

Common VFD Cooling & Ventilation Mistakes

- Ignoring ambient temperature limits

- No allowance for future drive upgrades

- Blocked fan intakes due to poor panel layout

- Using IP-rated drives where ventilation is still required

Recommended Categories for Proper Cooling

Example Drives & Use Cases

- Delta MS300 – compact drive, panel-mounted: Delta VFD4A8MS21AFSAA

- ABB ACS355 – industrial panel drive: ABB ACS355-03E-04A1-4

- ABB ACS880 – high-power systems with forced cooling: ABB ACS880-01-293A-3

FAQ

Do VFDs need ventilation even in sealed panels?

Yes. Heat must still be removed using heat exchangers or air conditioning.

What happens if airflow is restricted?

Thermal trips, derating, and long-term component damage.

Can I mount VFDs horizontally?

Only if the manufacturer explicitly allows it.

Need Help With Panel Design?

If you’re unsure about enclosure sizing, ventilation, or drive placement, we can help review your layout before issues occur.

Contact us: https://driveoutletmegastore.com/contact-us/