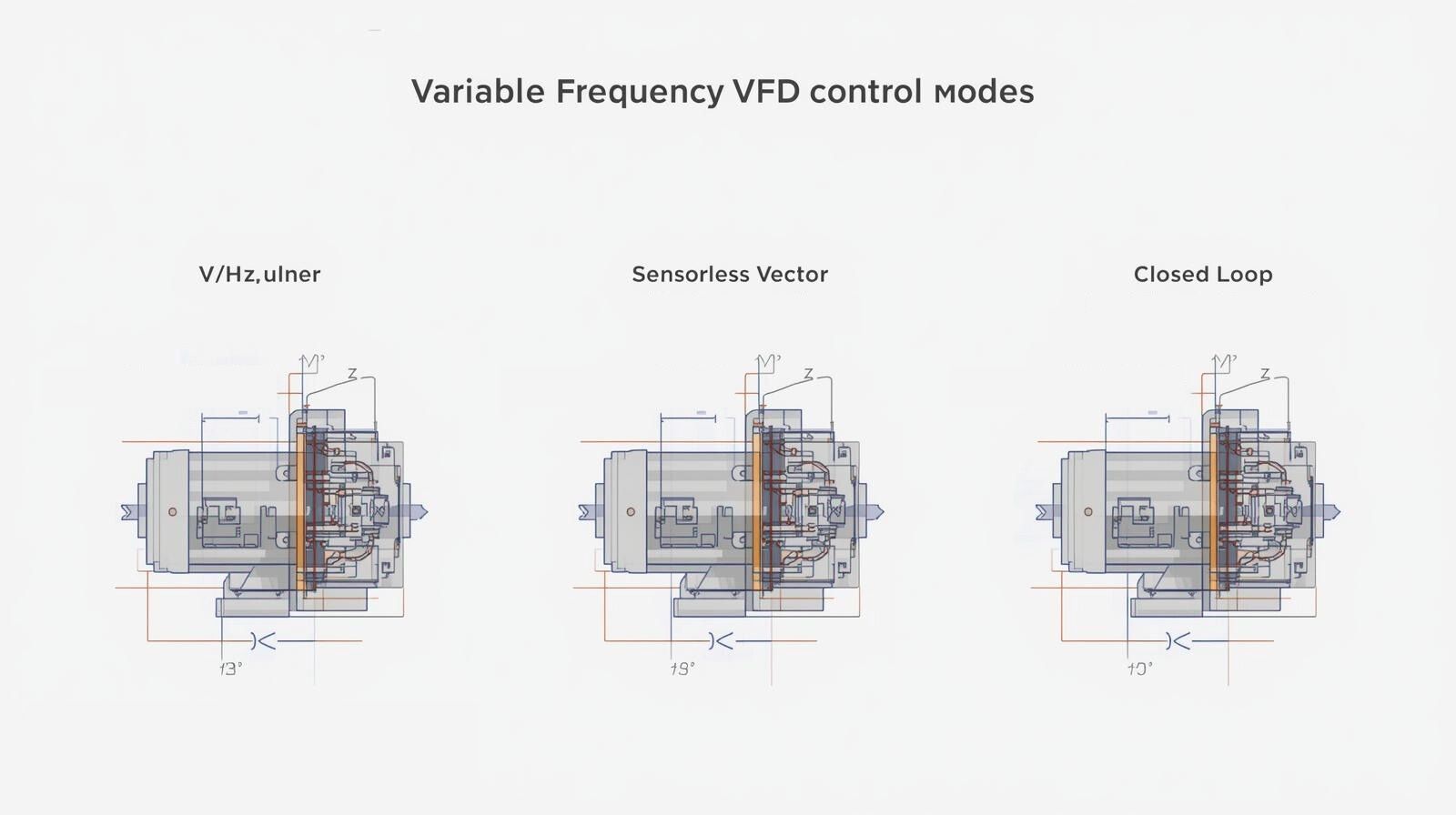

How to Choose the Correct VFD Control Mode: V/Hz vs Sensorless Vector vs Closed Loop

One of the most common reasons a VFD performs poorly — or fails prematurely — is the wrong control mode being selected.

Modern inverter drives offer multiple motor control methods, but choosing the wrong one can cause weak torque, unstable speed, overheating motors, nuisance trips, and unnecessary stress on the drive.

This guide explains V/Hz, Sensorless Vector, and Closed Loop control in plain terms — and shows you exactly when to use each.

Quick Links

- Why VFD control mode matters

- V/Hz (Volts per Hertz) control

- Sensorless Vector control

- Closed Loop (Encoder Feedback) control

- Control mode comparison table

- How to choose the right control mode

- Common setup mistakes

- Recommended drives & categories

- FAQ

Why VFD Control Mode Matters

The control mode defines how the VFD controls motor torque and speed. It directly affects:

- Starting torque

- Speed accuracy

- Motor heating

- Energy efficiency

- Drive lifespan

Using the wrong mode often looks like a “bad drive”, when in reality it’s a configuration issue.

This is one of the most common causes of issues discussed in: VFD Installation Mistakes That Cause Drive Failures

V/Hz Control (Volts per Hertz)

V/Hz is the simplest and most traditional control method. The drive increases voltage in proportion to frequency to maintain magnetic flux in the motor.

How it works

If frequency doubles, voltage doubles. Torque is assumed rather than actively controlled.

Best suited for

- Fans and pumps

- Lightly loaded conveyors

- Applications with predictable load

Advantages

- Simple to configure

- Stable for basic loads

- Low risk of instability

Limitations

- Weak low-speed torque

- Poor response to load changes

- Less efficient at partial load

V/Hz is often chosen by default — even when it’s not the best option.

Sensorless Vector Control

Sensorless Vector Control actively calculates motor torque and magnetic flux using current and voltage feedback — without an encoder.

This gives much stronger performance than V/Hz while keeping wiring simple.

Best suited for

- Conveyors

- Mixers and agitators

- Compressors

- Extruders

- General industrial machinery

Advantages

- Much higher starting torque

- Better speed regulation

- Improved energy efficiency

- No encoder required

Limitations

- Less accurate at zero speed

- Requires correct motor nameplate data

Related reading: What Is Sensorless Vector Control in a VFD?

Closed Loop Control (Encoder Feedback)

Closed Loop Control uses an encoder or resolver mounted on the motor shaft to provide real-time speed or position feedback.

This gives the highest accuracy and torque control available from a VFD.

Best suited for

- Hoists and cranes

- Winders and unwinders

- Elevators

- Precision process lines

Advantages

- Full torque at zero speed

- Exceptional speed accuracy

- Fast dynamic response

Limitations

- Higher cost

- More wiring and setup

- Encoder installation required

Closed loop control is often required for safety-critical or precision motion applications.

VFD Control Mode Comparison

| Feature | V/Hz | Sensorless Vector | Closed Loop |

|---|---|---|---|

| Starting Torque | Low | High | Very High |

| Speed Accuracy | Basic | Good | Excellent |

| Encoder Required | No | No | Yes |

| Setup Complexity | Low | Medium | High |

| Typical Applications | Fans, Pumps | Conveyors, Mixers | Hoists, Precision Systems |

How to Choose the Right VFD Control Mode

- Choose V/Hz if the load is light, predictable, and speed accuracy isn’t critical.

- Choose Sensorless Vector for most industrial machinery where torque matters.

- Choose Closed Loop if you need full torque at zero speed or precise motion control.

If torque is a concern, this guide helps: What Is Torque Control in VFDs and How It Improves Motor Efficiency

Common Control Mode Mistakes

- Leaving the drive in V/Hz when vector control is needed

- Incorrect motor nameplate data (kills vector performance)

- Using aggressive torque boost instead of correct control mode

- Expecting closed-loop performance without an encoder

Motor data errors are covered here: How to Read a VFD Nameplate

Recommended VFD Categories by Control Capability

- Inverter Drives (All Types)

- ABB Vector & High-Performance Drives

- Allen Bradley PowerFlex Drives

- Delta Inverter Drives

Example Drives by Control Mode

- ABB ACS355 – Sensorless Vector (general industrial): ABB ACS355-03E-04A1-4

- Allen Bradley PowerFlex 525 – Advanced vector control: Allen Bradley 25B-D017N114

- ABB ACS880 – Closed loop & high-performance applications: ABB ACS880-01-293A-3

FAQ

Can I switch control modes later?

Yes — but you must re-enter motor data and retune parameters. Always test under load.

Is sensorless vector always better than V/Hz?

Not always. For simple fan and pump loads, V/Hz can be perfectly adequate and more stable.

Do I need closed loop control for conveyors?

Usually no. Sensorless vector is sufficient unless precise positioning or zero-speed torque is required.

Need Help Choosing the Right Control Mode?

If you’re unsure which control mode suits your motor and application, send us your motor nameplate and load details.

Contact us: https://driveoutletmegastore.com/contact-us/